longitudinal compression test|Compression Testing: Exploring Methods, Applications, and : exporting Comparison of combined longitudinal compression and in-plane shear test results between different materials and test methods in the literature [14], [15] and the new results presented in this article. Two different data sets from [15] are included. Results are shown normalised with the uniaxial compression strength for each material.

Login. +245. Country. Phone. Password Forgot Password? Login. Don't have an account?

{plog:ftitle_list}

3. 4. 5. Next. Get free support for Cars & Trucks. Ask questions to Car and Truck experts, download service manuals & find help with repairs and installations.

Compression testing is a type of mechanical testing that involves applying a compressive force to a material and measuring its response. The compressive force tends to reduce the size of the material, and the test is designed to determine the material’s behavior under this type of load. During a compression . See moreCompression testing plays a crucial role in a wide range of contexts. Here’s why it’s so important: Material Selection: Compression testing is essential for selecting materials . See more

Flexure/Bend Testing: Flexure or bend testing involves applying a compressive load to a specimen in a way that induces bending or flexural deformation. This type of testing is . See moreCompression testing offers several significant benefits, making it a valuable tool in material science and engineering: Material . See moreThe results of longitudinal compression tests, using a Celanese Compression jig, on 914C carbon–epoxide composite with optical fibers running perpendicular to the reinforcement are .

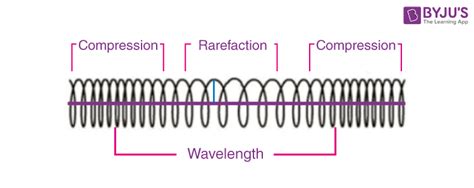

Comparison of combined longitudinal compression and in-plane shear test results between different materials and test methods in the literature [14], [15] and the new results presented in this article. Two different data sets from [15] are included. Results are shown normalised with the uniaxial compression strength for each material.Test: Longitudinal and Transverse Waves Quiz Practice. Name: Score: 18 Multiple choice questions. Term. amplitude. Highest point of a wave. Height of a wave. Longitudinal wave. . A combination of tension and compression. Lines in a plane that never intersect. A force that is applied in two opposite directions creates a tear or separation of . Uniaxial compression tests are conducted to obtain the compressive properties of materials. The compression test is preferred when the material undergoes large plastic strain during the loading since the plastic strain range is much larger as compared to the tension test due to the absence of necking (plastic instability).

Full-scale test on the mechanical behavior of longitudinal joints of NC-UHPC composite segments under compression-bending load Author links open overlay panel Bin-Yong Gao a b c , Ren-Peng Chen a b c , Huai-Na Wu a b c , Yang Zhang d , Fan-Yan Meng a b cMeasuring the compressive strength of a steel drum. In mechanics, compressive strength (or compression strength) is the capacity of a material or structure to withstand loads tending to reduce size (compression).It is opposed to tensile strength which withstands loads tending to elongate, resisting tension (being pulled apart). In the study of strength of materials, . For example, In terms of composite bearing and failure, longitudinal compression is a typical loading case and plays an important role in predicting the damage tolerance of structural components .

Longitudinal direct compression testing of a single polyacrylonitrile-based carbon fiber (T800S) is performed with a piezo-actuated testing machine installed in a scanning electron microscope, and the longitudinal compressive behavior of a carbon fiber is observed during loading. The compressive stress–compressive strain relation is linear in the early phase, and .

Longitudinal Compression

In this paper, a longitudinal compression experiment of composites was conducted and the macroscopic failure mode was obtained. Also, the microscopic failure morphologies of longitudinal compression and kink band were observed by using scanning electron microscopy. It can be seen that, under compression, fibers bend and form a kink . A longitudinal compression test for a single polyacrylonitrile-based carbon fiber (T300) was performed using a scanning electron microscope. The compressive stress/strain behavior was initially linear, but subsequently became nonlinear. The longitudinal tangent modulus decreased with increasing compressive strain. Average stress–strain compression test curves in the longitudinal direction. The stiffness of compressed pine differs significantly from that of the compressed spruce. This is presumably due to the different wood species and test specimen geometry since the test specimens of the series carried out at UOL were following the standard EN408, i.e .For example, the average strength of a compact human bone in Reilly and Burstein [23] was 105 MPa in a longitudinal compression test, and 131 MPa in a transversal compression test. The average longitudinal strength in tension in the same experiment was .

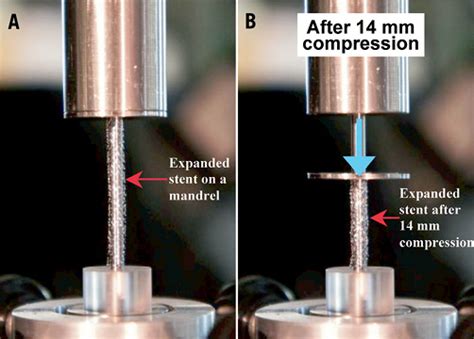

We previously compared longitudinal strength (the ability of a stent to resist longitudinal distorting forces) for 7 different stent designs using compression and elongation bench tests. 7 The compression test involved relating the force applied to the circumference of the proximal hoop of a stent to the extent of stent compression. Other investigators used a . Among these experimental data, it is found that a large scatter occurs in the measured longitudinal compression strengths of the 3D printed continuous carbon fiber reinforced composites (from 224 MPa [20] to 426 MPa [16]).In addition, waved filaments are observed when using the default process parameters [26] which should be inevitable in the 3D .

Using the developed compression test setup, measuring larger values for the static and dynamic longitudinal compressive strength, X c, of an IM7/8552 UD laminate than in an earlier study [7] proved possible while quantitatively verifying the strain-rate effect on this material property. It was thought that the values measured for the UD .

The test configuration is introduced in Section 2, and the data reduction method is detailed in Section 3. The results are presented and discussed in Section 4, . A study on the longitudinal compression strength of fibre reinforced composites under uniaxial and off-axis loads using cross-ply laminate specimens.the test tends to a pure compression test. In the present study, large eccentricities, equal to half of the total thickness of the tested specimen, are used in order to obtain quasi-pure bending moment in the gauge length. Figure 2 : a) Presentation of the compression with pivots experimental device, b) load/displacement The true strain is therefore less than the nominal strain under tensile loading, but has a larger magnitude in compression. While nominal stress and strain values are sometimes plotted for uniaxial loading, it is essential to use true stress and true strain values throughout when treating more general and complex loading situations. The longitudinal compression tests of unidirectional carbon fiber/nanoparticles reinforced polymer composites laminates were conducted to validate the simulated results. The nanoparticles distribution of specimens were observed by the scanning electron microscope (SEM) observations. . Longitudinal direct compression test of a single .

We previously compared longitudinal strength (the ability of a stent to resist longitudinal distorting forces) for 7 different stent designs using compression and elongation bench tests. 7 The compression test involved relating the force applied to the circumference of the proximal hoop of a stent to the extent of stent compression. Other investigators used a . In this paper, a longitudinal compression experiment of composites was conducted and the macroscopic failure mode was obtained. Also, the microscopic failure morphologies of longitudinal compression and kink band were observed by using scanning electron microscopy. It can be seen that, under compression, fibers bend and form a kink . In the standard compression tests on 0 °-specimens, the plies are subjected to a pure compression stress σ 11 in the longitudinal direction, assuming perfect load transmission at the ends of the specimen. In the proposed test, the central 90 °-ply is submitted to both longitudinal compression stress σ 11 and transverse tensile stress σ 22 . The determination of the lamina longitudinal compression strength remains an unsolved problem. Non-valid failure modes are commonly observed in compression tests of unidirectional specimens. . "An Improved Engineering Test Method for the Measurement of the Compressive Strength of Unidirectional Composites," ECCM-CMS Conf. Proc., pp. 101-111 .

prone-flexion compression. Thessaly test. standing at 20 degrees of knee flexion on the affected limb, the patient twists with knee external and internal rotation with positive test being discomfort or clicking. . vertical and longitudinal tear. rather than radial, horizontal or degenerative tear. bucket handle meniscus tear.From the data generated using the longitudinal compression test method, the amount of longitudinal compression for each sample of a particular stent design was determined at a load of 50 gf. Table 2 lists the average longitudinal compression under the applied force of 50 gf for each of the 14 stent designs tested. In addition to the average .

The longitudinal compression strain limit is defined as follows: [18.2] ε cp = 1.76 t D and ≤ 4 % Test data from the available papers are plotted in Figure 18.3 , with calculated strains from Eq. Recently, the quantitative relationship between the interphase properties and mechanical performances of the silica reinforced resin matrix have been established by numerous analytical models [[19], [20], [21]].Especially, the modified Halpin-Tsai model predicts that the increase of thickness and modulus of interphase lead to the enhancement of elastic modulus .

Engineering assessment of the longitudinal compression behaviou

WEB19 de set. de 2023 · From left: Aurora Nischevi, Emily Roberts, Abigail Morris, Lizzie Mayland and Georgia Davies of The Last Dinner Party photographed by Nicole Nodland on August 30, 2023 in London.

longitudinal compression test|Compression Testing: Exploring Methods, Applications, and